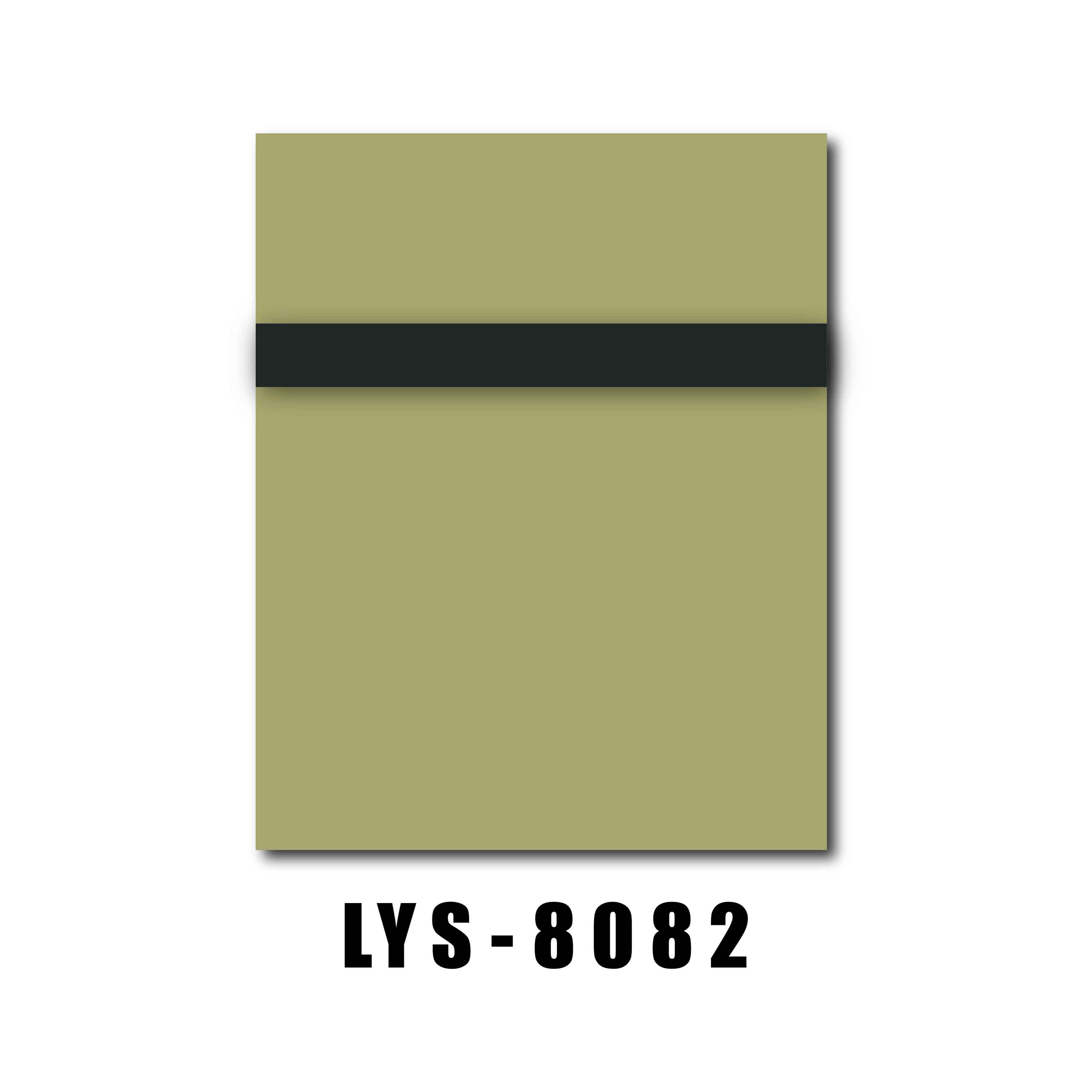

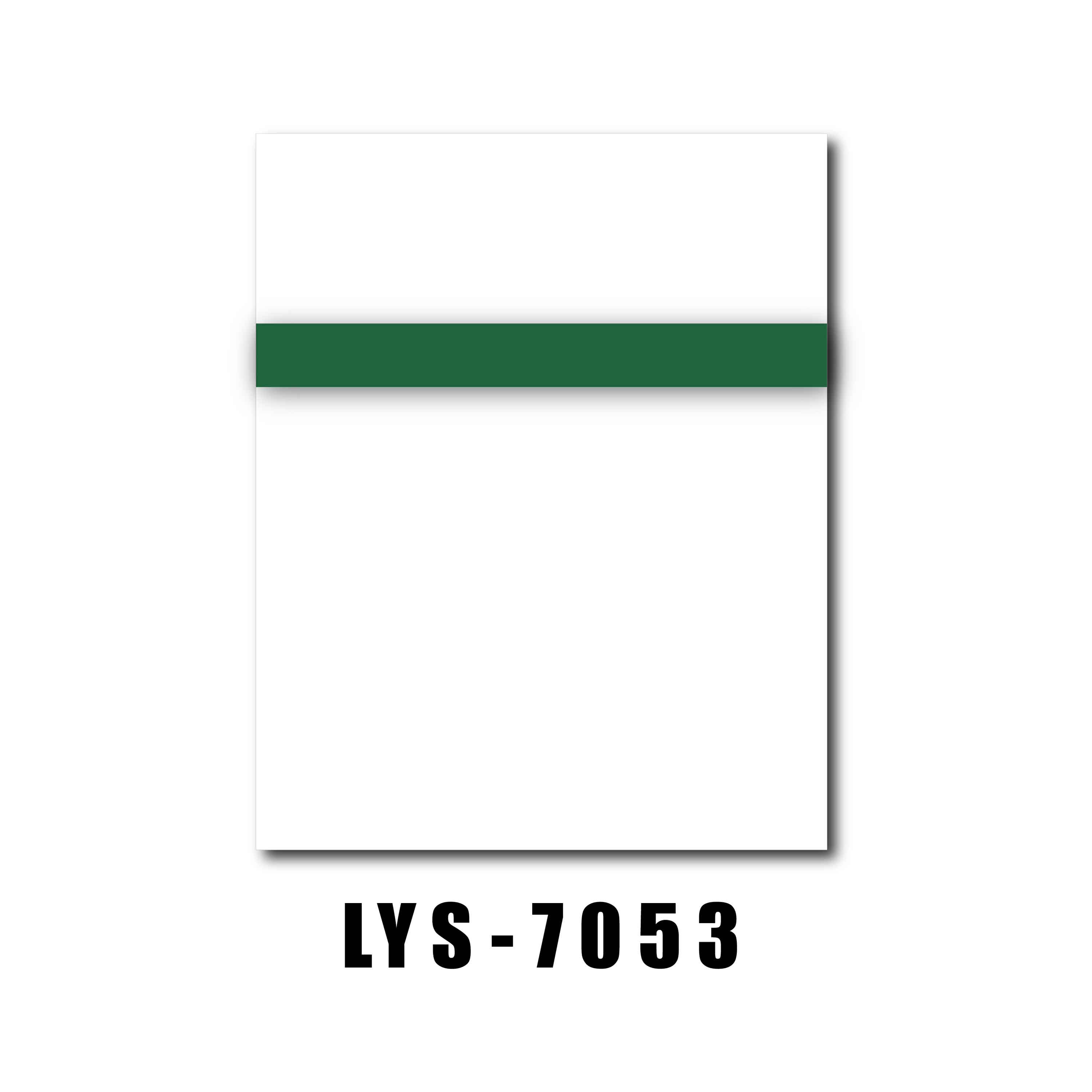

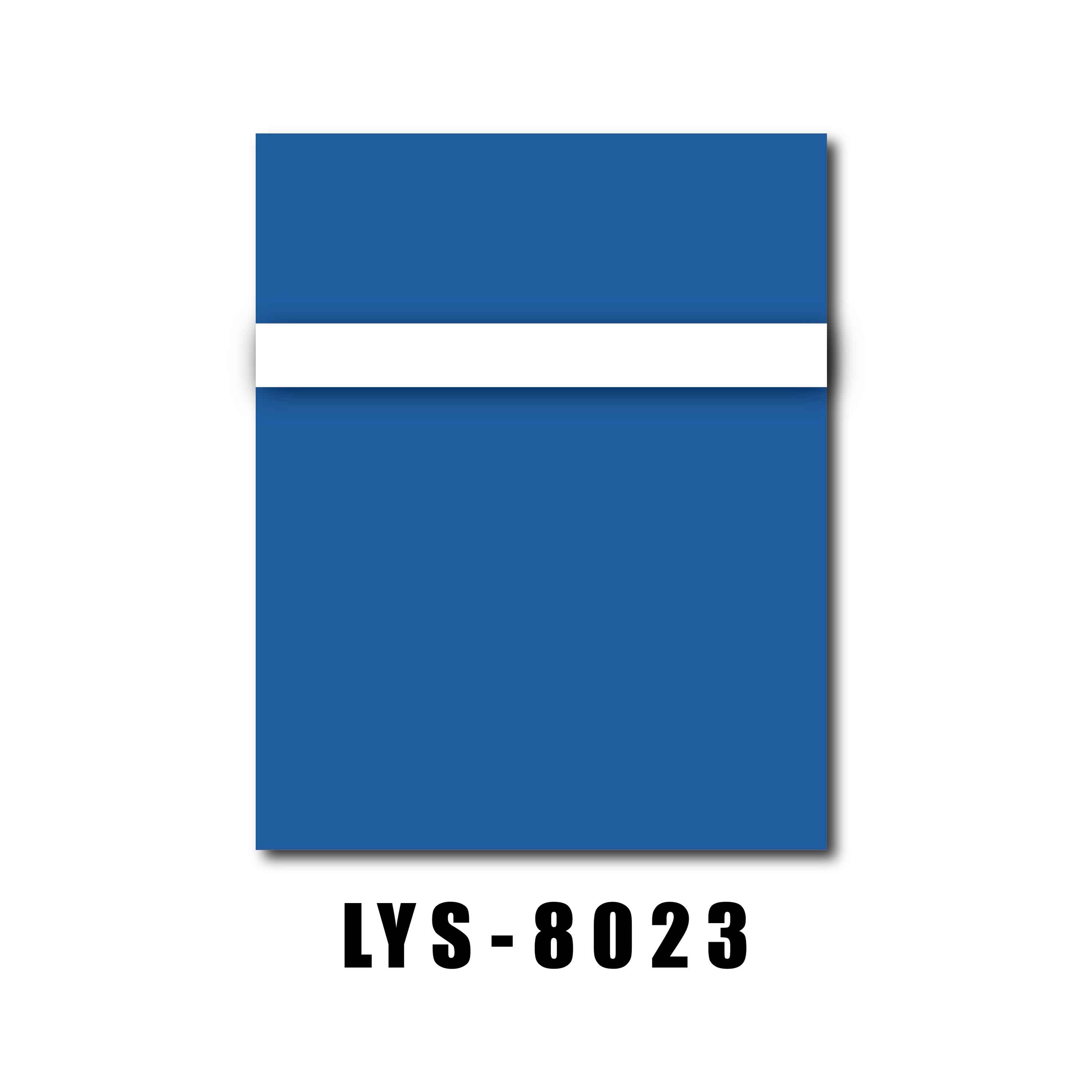

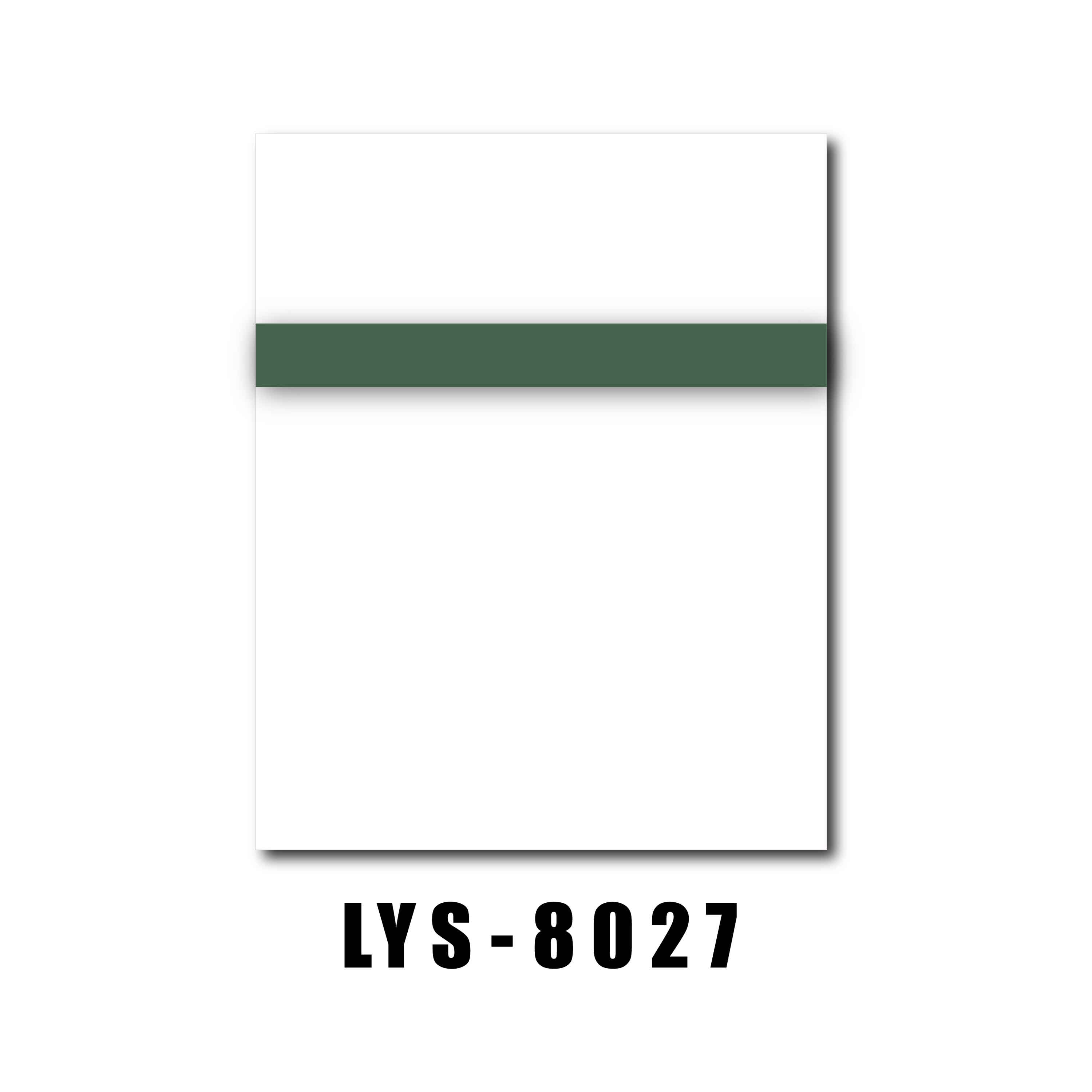

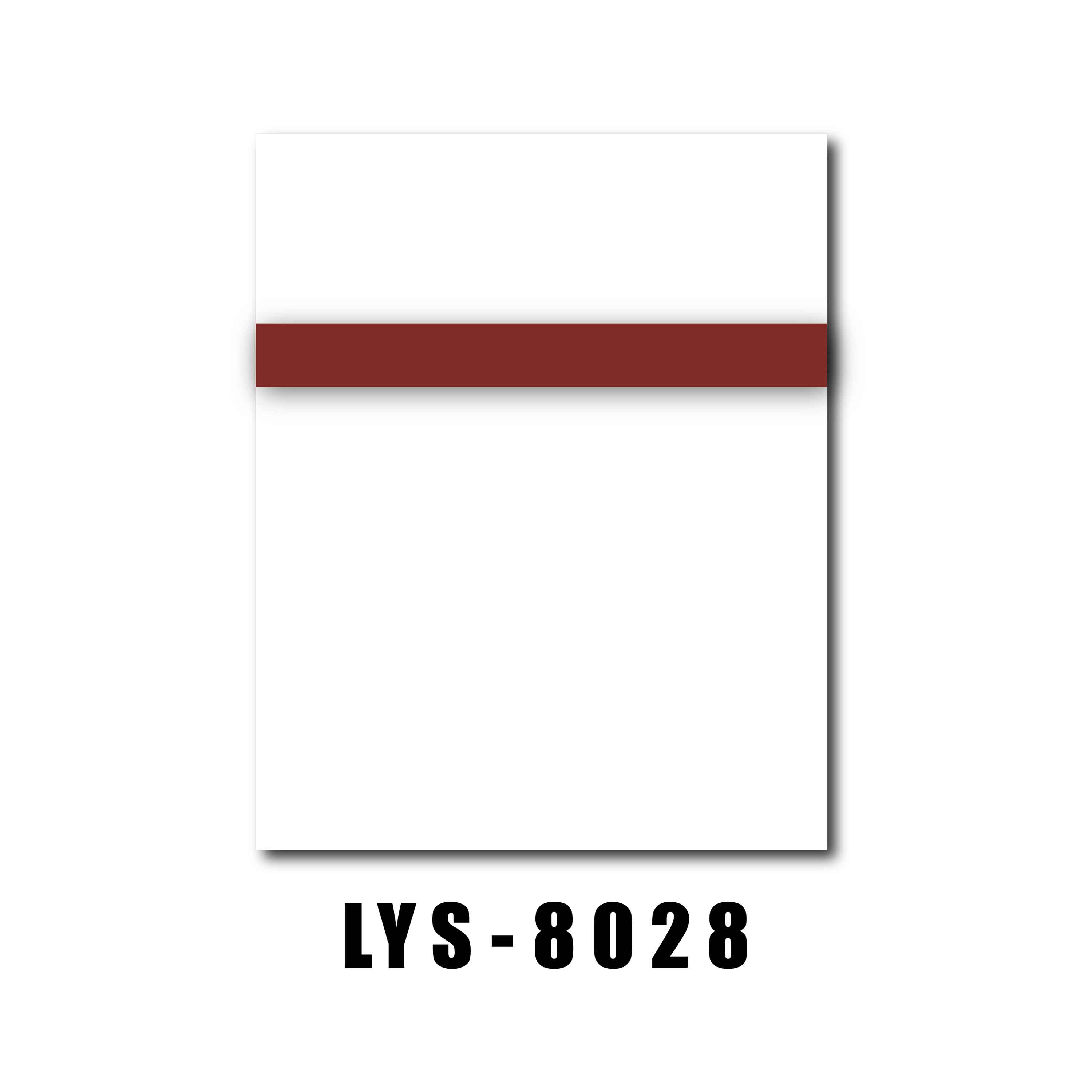

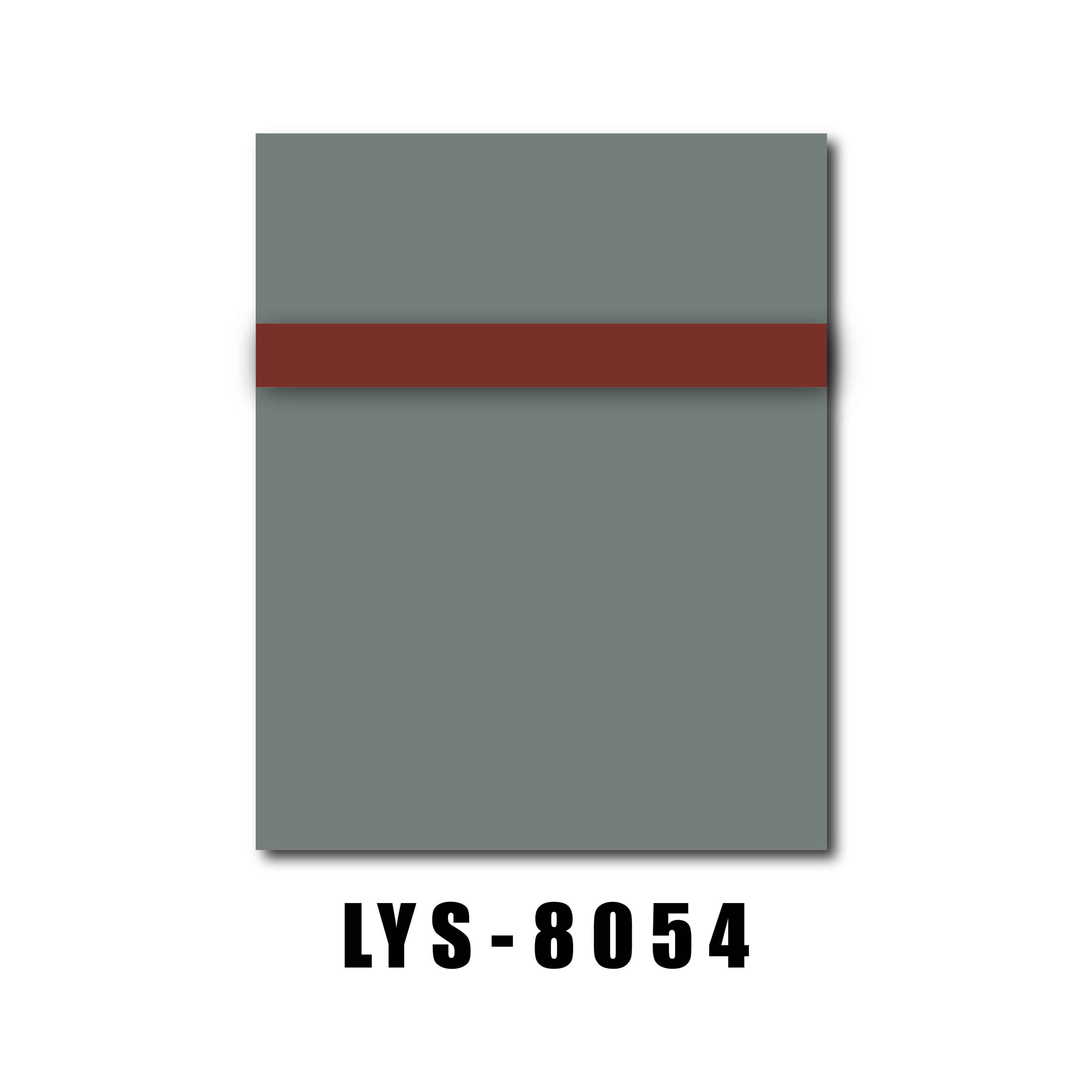

Dark Green ABS Double Color Plastic Sheet

Send Inquiry

Dark Green ABS Double Color Plastic Sheet is one of the most widely used plastics. As a result of its high impact resistance and suitability for heavy duty applications, ABS has found wide acceptance in the refrigeration and automotive industries, as well as for the printing and display markets. ABS is particularly suitable for vacuum forming.Dark Green ABS Double Color Plastic Sheet is used in a wide variety applications including trim and accessory panels on trucks and cars. Laminated with an acrylic film exterior, ABS sheets have replaced traditional metal materials due to its ease of formability, increased durability, and better weather ability. ABS sheet is one of the most widely used thermoplastics that we offer. Its high rigidity and impact strength combine with its excellent abrasion resistance to make it the ideal material for a wide variety of applications.

|

item |

Double color sheet/ABS sheet |

|

Place of Origin |

China |

|

Model Number |

Laser engraving |

|

Material |

ABS |

|

Thickness |

0.3-3mm |

|

Size |

610*1220mm, 600*1200mm, 305*610mm |

|

Processing Service |

Cutting, Moulding |

|

Surface |

glossy and matte |

|

Minimum Temperature: |

-4°F -20°C |

|

Melting Poin: |

221°F 105°C |

|

Usage |

suitable for outdoors |

Feature and application of Dark Green ABS Double Color Plastic Sheet:

Feature:

The most important mechanical properties of ABS are impact resistance and toughness.

A variety of modifications can be made to improve impact resistance, toughness, and heat resistance.

The impact resistance can be amplified by increasing the proportions of polybutadiene in relation to styrene and also acrylonitrile, although this causes changes in other properties. Impact resistance does not fall off rapidly at lower temperatures.

Stability under load is excellent with limited loads.

Application scenarios:

ABS's light weight and ability to be injection molded and extruded make it useful in manufacturing products such as drain-waste-vent (DWV) pipe systems, musical instruments (recorders, plastic clarinets, and piano movements), golf club heads (because of its good shock absorbance).Automotive trim components, automotive bumper bars, medical devices for blood access, enclosures for electrical and electronic assemblies, protective headgear, whitewater canoes, buffer edging for furniture and joinery panels, luggage and protective carrying cases, small kitchen appliances, and toys, including Lego and Kre-O bricks.Household and consumer goods are the major applications of ABS. Keyboard keycaps are commonly made out of ABS.

Details of the Dark Green ABS Double Color Plastic Sheet

FAQ:

Q: How can I get a sample?

A: Before start your sampling, we need to confirm product details with you including specification to avoid any possible misunderstanding.

Q: How long for sampling?

A: It usually needs 2 days. The actual time is up to how many sample orders we receive.

Q: What’s MOQ?

A: The MOQ is 300PCS

Q: If I have some idea, can you help me?

A: Yes, we would be very pleased to do it. Once you have some idea please send it to us. We would be able to assist you to finish it.